Mannheim

Pankl Turbosystems GmbH

| Division | Racing |

| Technology | Machining, Additive |

| Products | Charging Systems |

| Certifications | ISO 9001 |

Die Pankl Turbosystems GmbH wurde 2009 in Mannheim gegründet und ist eine ISO9001 zertifizierte Tochtergesellschaft der Pankl Racing Systems AG.

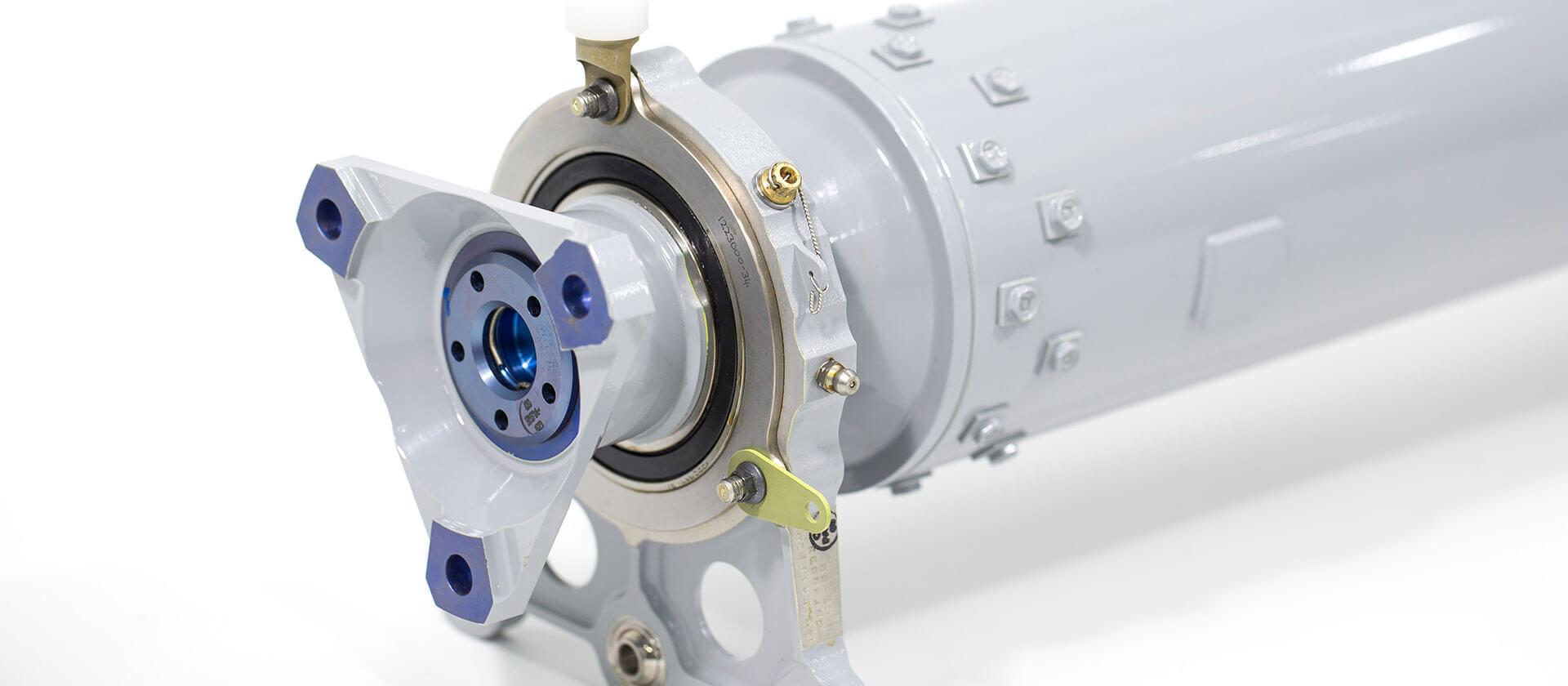

Die Systemkompetenz der Pankl Turbosystems liegt in der Entwicklung, dem Testen und der Produktion von innovativen Aufladesystemen für verschiedenste Motorsport, High Performance, Nutzfahrzeug, Off-Road, Luftfahrt und Brennstoffzellenanwendungen. Neben Komplettentwicklungen bieten wir auch Engineering Dienstleistungen in den Bereichen Konstruktion und Simulation sowie Versuchsdienstleistungen für herkömmliche und elektrisch unterstützte Aufladesysteme an. Zu unseren Kompetenzen zählen: modernste Testeinrichtungen, ein Heißgasprüfstand in Kombination mit einem Batteriesimulator, Kundenspezifische Validierungsprogramme, Assemblierung anspruchsvoller Prototypen und Kleinserien mit höchsten Qualitätsanforderungen.

UNSER PRODUKTPORTFOLIO

- High-Performance Abgasturbolader mit Wastegate / VTG-Regelung

- Mehrstufige Aufladesysteme

- Elektrisch unterstütze Turbolader (EAT)

- Elektrische Kompressoren

- Turbocompund-Generatoren (Nutzturbine)

- Brennstoffzellenluftversorgungssysteme (FCAS)

Forschung & Entwicklung

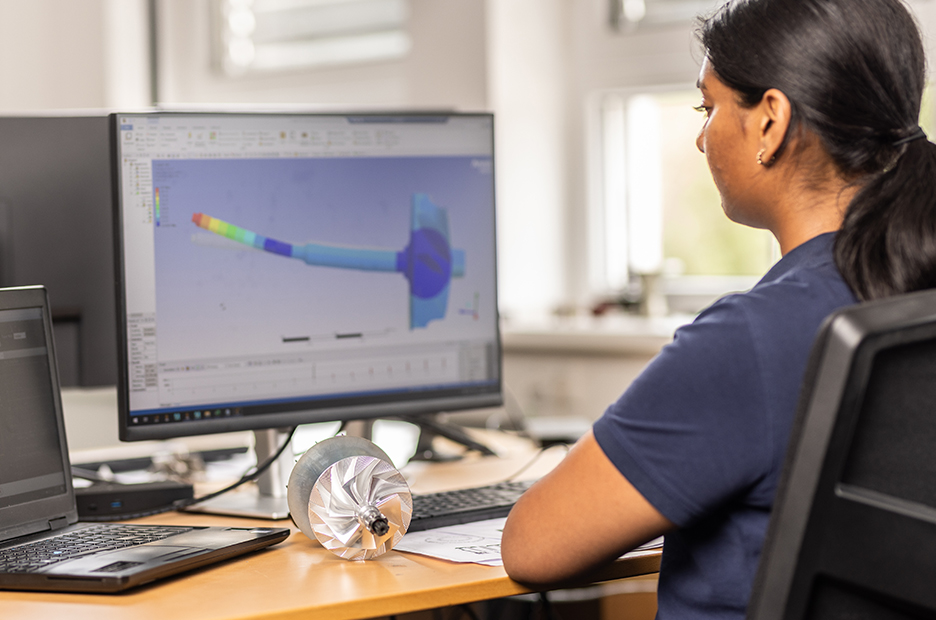

Als innovativer Anbieter von Aufladesystemen, verfügt Pankl Turbosystems über ein breites Spektrum an Entwicklungskompetenzen.

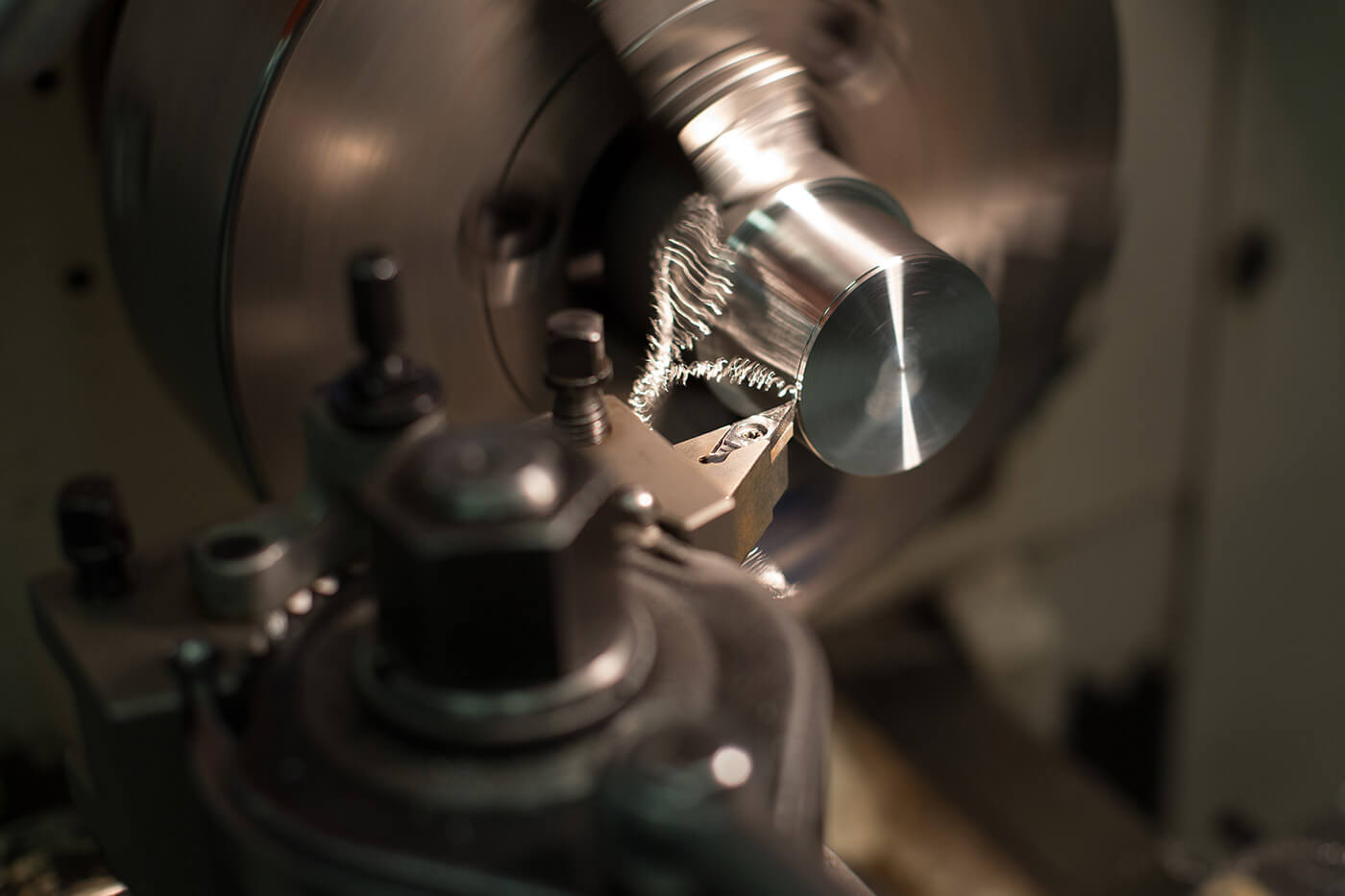

- Auslegung und Berechnung von drehenden sowie statischen Bauteilen

- Bauteil- und Systemkonstruktion, inklusive 3D, 2D und Stücklisten-Erstellung

- Elektrik und Elektronik (E-Motoren und Leistungselektronik)

- Validierung an Komponenten- und System-Prüfständen

System Engineering (V-Modell)

Das Systems Engineering spielt bei Pankl Turbosystems eine zentrale Rolle, was die Entwicklung mit einem gesamtheitlichen Ansatz angeht. Dies ist insbesondere für komplexe Systeme wie elektrische Verdichter oder Turbolader erforderlich, da unterschiedlichste Themengebiete wie Lagersysteme, Strömungskomponenten oder elektrische Antriebe integriert werden müssen. Basierend auf den mit den Kunden abgestimmten Anforderungen wird ein Entwicklungsprozess nach dem „V-Modell“ verfolgt, bei dem eine enge Verknüpfung zwischen der Auslegung und dem Design Verification Plan (DVP) herrscht.

Unsere Entwicklungsleistungen

Montage

Turbolader, Brennstoffzellen-Luftversorgungssysteme (FCAS) sowie elektrisch unterstützte Turbolader (EAT) -Systeme werden mittels unserem ERP System kommissioniert, sodass eine Rückverfolgbarkeit jeder Komponente zu 100% garantiert ist. Der Montageprozess zeichnet sich hierbei durch eine flexible Anpassung an Kundenanforderungen und Stückzahlen aus, optimiert auf Basis langjähriger Industrieerfahrung.

- Prototypen und Kleinserienmontage

- Stückzahlen bis 10.000 Einheiten

- ERP geführtes Teilemanagement

- Einzelteil- und Betriebsauswuchten

- Integrierte Qualitätsprüfungsschritte

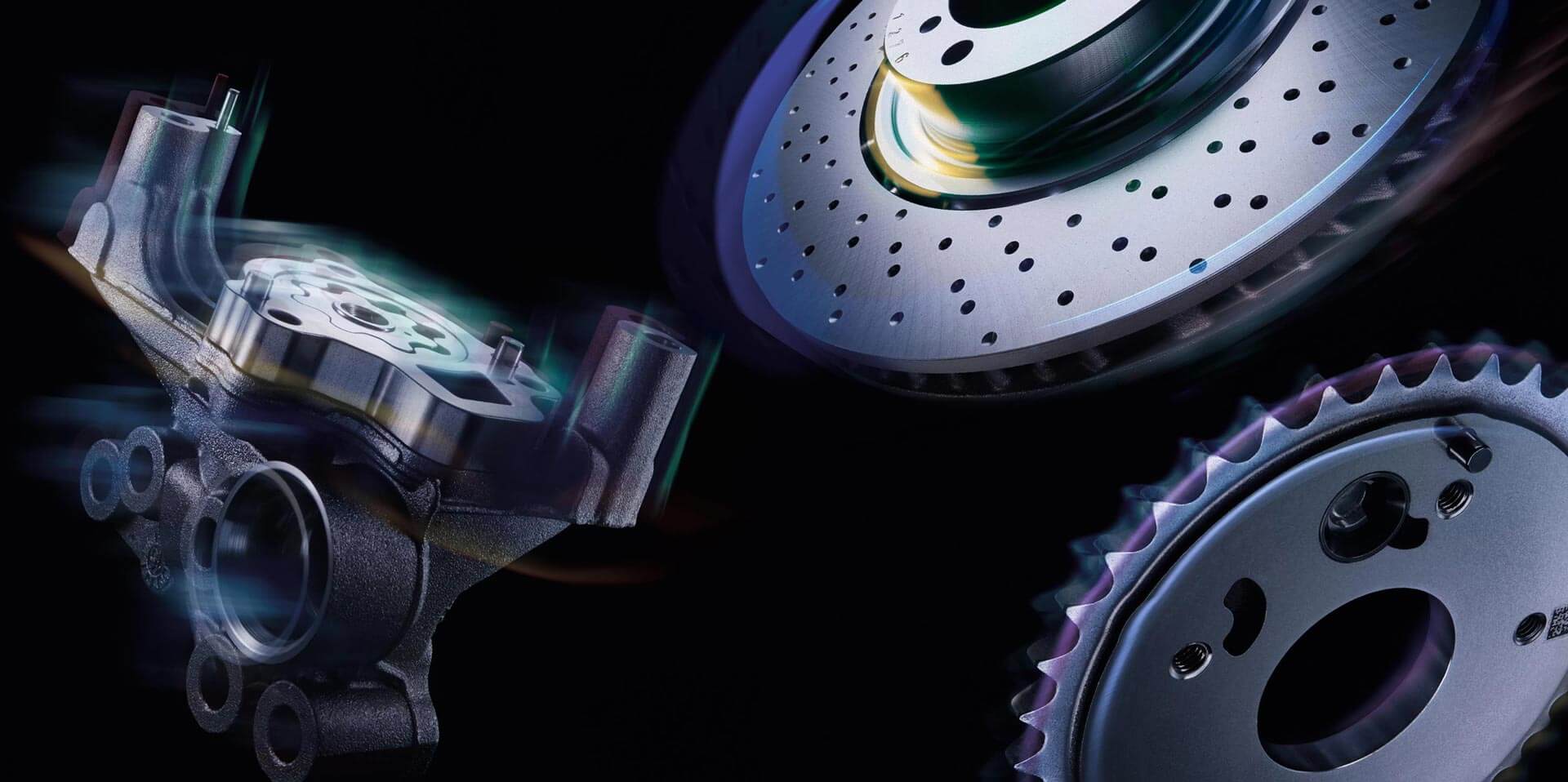

Qualität

Das hochentwickelte und integrierte Qualitätsmanagementsystem von Pankl Turbosystems stellt sicher, dass unsere Produkte dem hohen Vertrauen, welches unsere Kunden uns schenken, entsprechen. Alle relevanten Prozesse sind durch unsere Kunden sowie Zertifizierungsstellen (ISO 9001) zugelassen, und werden regelmäßig überprüft und verbessert. Wir verfügen über die Möglichkeit der Materialprüfung in einem eigenen Labor und der zerstörungsfreien Werkstoffprüfung nach allen gängigen Methoden.

Jedes Produkt wird bei uns versuchsseitig geprüft, sodass systemrelevante Parameter jederzeit nachvollzogen werden können.

- Wuchtgüte von Einzel- oder Systemkomponenten

- Feldstärkenmessung von Rotoren

- Bestimmung elektromagnetischer Konstanten im Betrieb

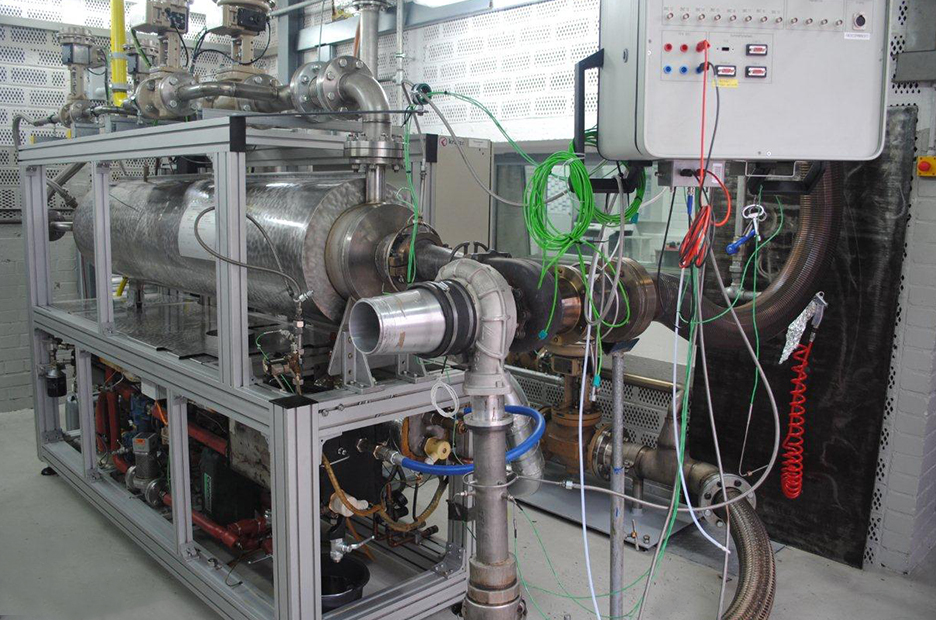

Test

Pankl Turbosystems bietet ein umfassendes Spektrum an Prüfdienstleistungen im Bereich der Aufladesysteme, das von kundenspezifischen Einzelprüfungen bis hin zu kompletten Validierungsprogrammen reicht. Zu unserer Ausstattung gehören 3 Prüfstande für konventionelle und elektrische Aufladesysteme. Diese sind jeweils an die spezifischen Validierungsanforderungen angepasst und mit Sonderequipment ausgestattet, wie z.B. geschlossener Verdichterkreislauf (Compressor Closed Loop Unit). Weitere Einzelkomponentenprüfstände sind vorhanden, wie z.B. ein Luftlagerprüfstand zur Abbildung unterschiedlicher Lastkollektive.

Spezifikationen der Prüfstände

- Thermodynamische Vermessung (Verdichter- und Turbinenkennfelder)

- Erweiterte Turbinenkennfeldmessung mittels CCLU (Compressor Closed Loop Unit)

- Funktionstests für elektrisch unterstützte Aufladesysteme mit Batteriesimulator

- Automatisierte Dauerläufe nach vorgegebenen Lastzyklen

- Rotordynamik / Wellenbahnmessungen

- Akustik- und Schwingungsmessungen

- Thermo-Schock Tests

- High-Cycle-Fatigue-Tests, einschließlich optischen Tip-Timings von Turbinen- und Verdichterschaufeln

- Berst- & Containment-Tests

- Materialerprobungen für Abgasturbolader, Abgaskrümmer, Abgasanalagen

- Funktionstests für Wastegates / VTGs / Aktuatoren

Karriere

Werde Teil unseres Teams!

Unsere offenen Stellen

Rodrigo Costa

Director Sales

Telefon: +49 621 860 854 435

E-Mail: [email protected] or [email protected]

Adrien Kopp

Director Innovation

Telefon: +49 621 860 854 0

Gerhard Krachler

Managing Director

Telefon: +49 621 860 854 0